The race for outside-China sourcing has intensified, particularly since the U.S. underwent a political shift, pushing businesses to diversify their supply chains. While many manufacturing techniques are easily sourced globally, some specialized techniques require significant investment and expertise. In this article, we’ll explore three key metalworking processes—hot pressing, hot forging, and cold pressing (cold dropping)—and their sourcing challenges outside of China.

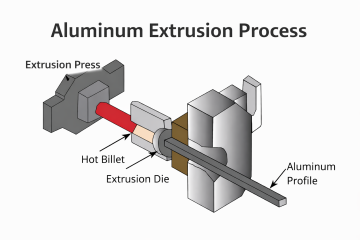

What is Hot Pressing?

Hot pressing is a high-temperature metalworking process where heat and pressure are applied simultaneously to shape or bond materials. The process begins with steel sheet material heated to a specific forming temperature until it becomes soft and malleable. Once heated, the material is passed through a stamping machine, where it is shaped and formed according to precise specifications.

Key Features of Hot Pressing:

- Requires high heat and controlled pressure.

- Produces durable, high-strength components.

- Used in industries such as automotive, aerospace, and heavy machinery.

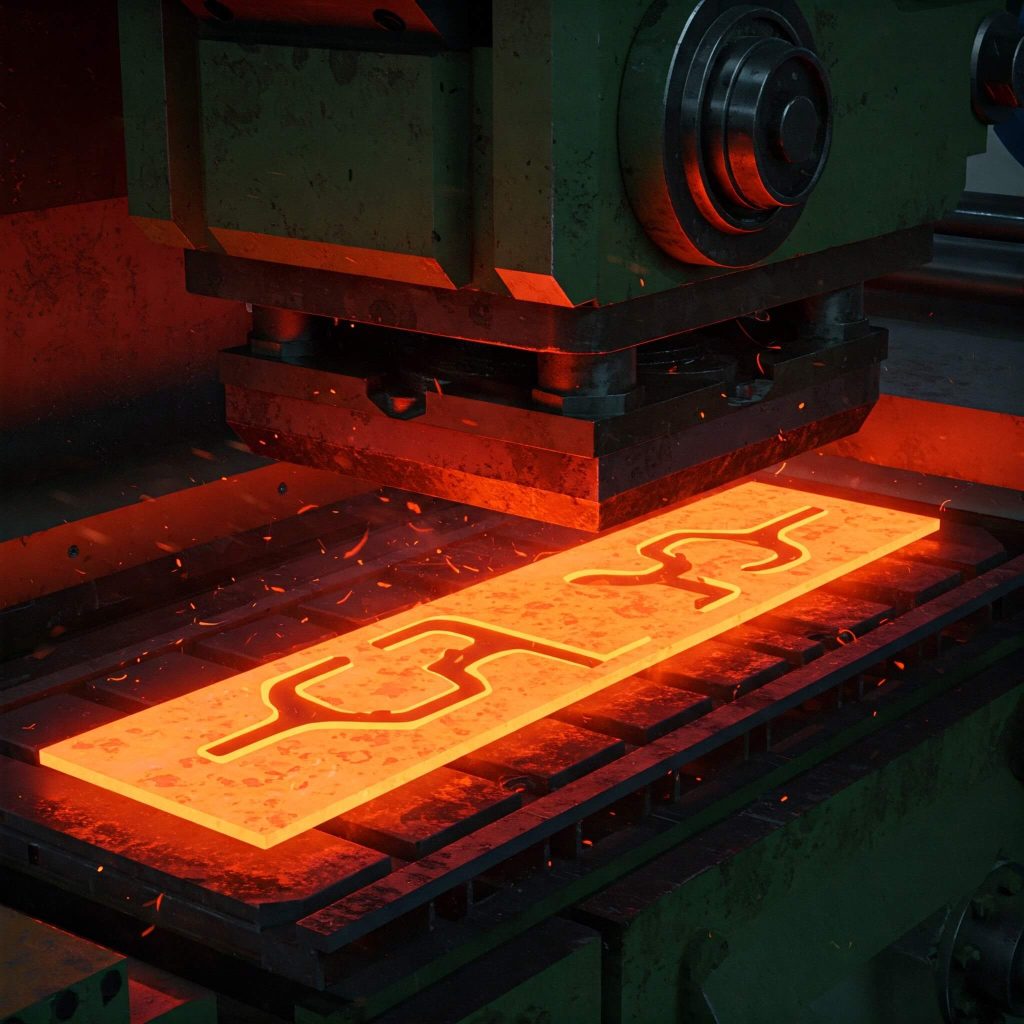

What is Hot Forging?

Hot forging is another high-temperature metalworking technique where solid raw material is heated until it becomes pliable. Once heated, the metal is shaped using dies and high-pressure stamping machines. While hot forging is similar to hot pressing, the key difference lies in the raw material: hot forging starts with a solid metal billet rather than a sheet.

Key Features of Hot Forging:

- Produces strong and impact-resistant metal parts.

- Requires precise temperature control to maintain material integrity.

- Commonly used for automotive, construction, and heavy industrial applications.

What is Cold Pressing (Cold Dropping)?

Cold pressing, also known as cold dropping, shapes materials under high pressure without applying heat. The process starts with thin metal sheets at room temperature, which a stamping machine presses into the desired shape using a die.

Key Features of Cold Pressing:

- No heating required, making it more energy-efficient.

- Suitable for lightweight and cost-effective metal parts.

- Frequently used in the electronics, packaging, and appliance industries.

Sourcing Challenges Outside of China

While these techniques are relatively common in China, sourcing them in Southeast Asia (SEA) and other regions presents several challenges:

- Limited Supplier Base: Hot pressing, in particular, requires highly specialized suppliers, and it is nearly impossible to find suitable providers outside of China.

- High Capital Investment: The machinery and technology required for hot pressing and hot forging are capital-intensive, deterring smaller factories from investing.

- Lack of Skilled Workforce: These processes require technical expertise, which remains concentrated in established manufacturing hubs like China.

- Industrial Classification: SEA countries classify hot pressing and hot forging as heavy industrial and high-tech processes, enforcing strict regulations and limiting their adoption.

Conclusion

For businesses looking to diversify their supply chains, hot pressing, hot forging, and cold pressing present significant sourcing challenges outside of China. While some suppliers exist in Southeast Asia, they are few and highly selective. Companies requiring these processes must conduct thorough due diligence and consider long-term partnerships with specialized manufacturers to ensure quality and efficiency.

For those exploring alternative sourcing options, working with experienced supply chain specialists can streamline the search for reliable partners. Understanding the complexities of these manufacturing techniques is key to making informed sourcing decisions in today’s evolving global market.

To know more or further support, please find us HERE

Thank you.