Glass fiber extrusion and pultrusion are critical processes in the composites industry. Both techniques support the production of high-strength, lightweight materials used in infrastructure, chemical facilities, marine applications, and wastewater treatment. Although these two methods serve similar applications and use comparable materials—typically fiberglass reinforcement and thermoset resins—their manufacturing processes differ significantly. As a result, suppliers specializing in each technique are often different. Understanding both processes in detail can help businesses source the right suppliers when manufacturing in Vietnam, improving accuracy and efficiency in supplier selection. Vietnam is emerging as a reliable destination for composite component production, particularly in the FRP (Fiber Reinforced Polymer) segment.

Glass Fiber Extrusion Manufacturing in Vietnam

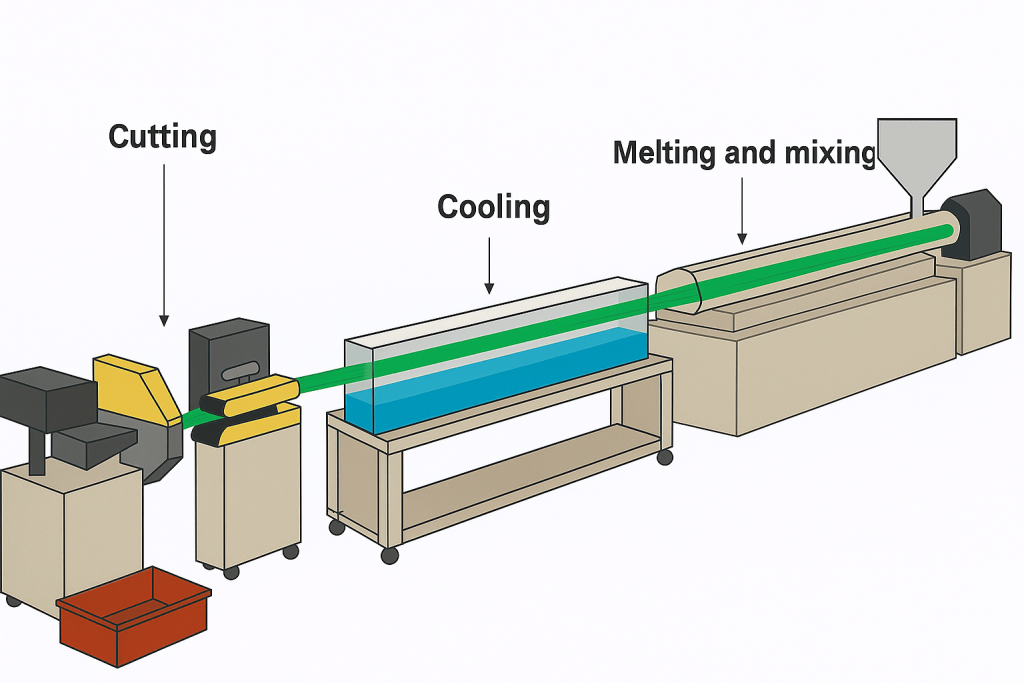

While many Vietnamese suppliers are experienced in standard plastic extrusion (PVC, HDPE, uPVC, ABS), only a small number have mastered fiberglass-reinforced plastic extrusion, and for good reason:

- High technical complexity

Mixing fiberglass with thermoplastics requires precise temperature, shear rate, and screw configuration control to ensure uniform distribution and structural integrity. - Tooling and equipment challenges

Glass fiber is highly abrasive. Over time, it causes significant wear on barrels, screws, and extrusion dies, which necessitates special-grade steel and frequent maintenance. - Limited local market demand

Applications for fiberglass-reinforced profiles (e.g. electrical conduit, structural components) remain niche in Vietnam. As a result, few manufacturers are willing to invest in the necessary R&D and equipment.

Recognizing this market gap, we collaborated closely with local extrusion partners to successfully develop fiberglass extrusion capabilities in Vietnam. Because of this strategic effort, we can now support product development and local production of fiberglass-reinforced plastic tubes and profiles — something few other sourcing partners in Vietnam can offer.

Pultrusion FRP Pipe Manufacturing in Vietnam

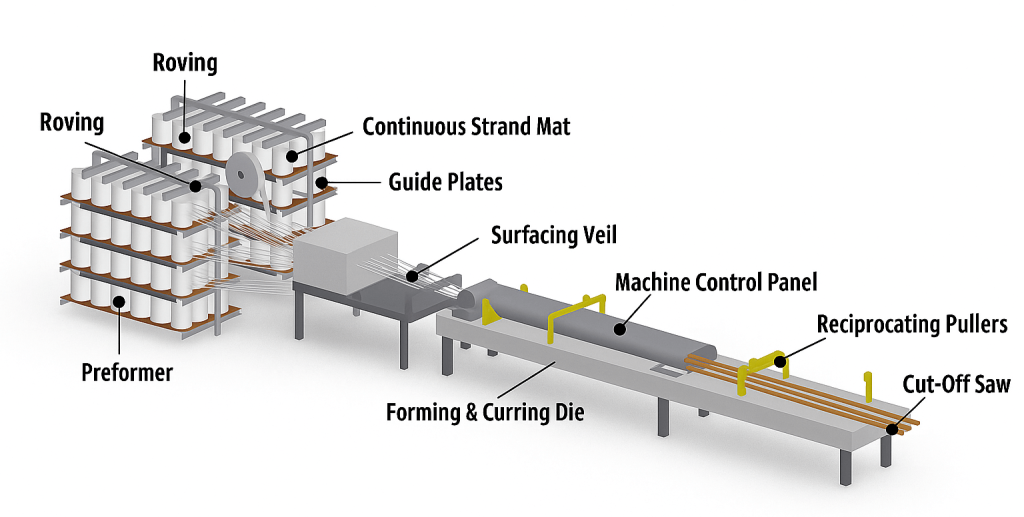

Pultrusion is a continuous manufacturing process used to produce fiber-reinforced polymer (FRP) profiles with consistent cross-sections. It is ideal for creating strong, lightweight, and corrosion-resistant components such as pipes, rods, beams, gratings, and other structural parts. This process combines pulling and shaping through a heated die, which differentiates it from extrusion.

In recent years, manufacturing in Vietnam has expanded to include pultrusion as a key production method for high-performance composite materials. This shift supports growing demand from industries such as water treatment, chemical processing, telecommunications infrastructure, and construction.

Key Steps in the Pultrusion Process

- Reinforcement Feeding

Continuous fibers (e.g., glass, carbon, or aramid) are pulled from creels in the form of rovings, mats, or fabrics. These fibers are the primary source of mechanical strength. - Resin Impregnation

The fibers are drawn through a resin bath, where they are saturated with thermosetting resin (polyester, vinyl ester, or epoxy). Additives like UV stabilizers, pigments, or fire retardants may be added to the mix. - Preforming

The wet fibers pass through preformers that align and shape the material, remove excess resin, and begin forming the target profile geometry. - Heating and Curing

The preformed material enters a heated die, where the resin cures under controlled temperature and pressure. The die defines the final shape and dimension of the profile. - Pulling

A caterpillar puller continuously pulls cured material through the die at a steady speed, maintaining consistency and structural strength. - Cutting

The system automatically cuts the continuous profile to the specified length based on customer requirements

Conclusion: Why Vietnam for Glass Fiber-Based Manufacturing

Vietnam’s composite sector is gaining attention due to its cost-effectiveness, improving technical capabilities, and strategic location. Although the country does not yet produce raw glass fiber, its growing ecosystem for pultrusion, resin formulation, and fiberglass processing makes it a promising hub for FRP manufacturing.

For companies seeking to diversify their supply chains or embrace the China+1 strategy, manufacturing in Vietnam offers a compelling combination of skilled labor, export readiness, and scalability.

To know more or further support, please find us HERE