Plastic Injection Sourcing Vietnam is growing fast. Vietnam now has hundreds of factories that offer plastic injection services. Many of them work with common materials such as PP, PE, ABS, and HIPS. Because the supply base is wide, buyers often believe that sourcing in Vietnam is simple.

However, when a project needs engineered plastics or high-performance materials, the situation becomes more complex. At that point, choosing the right supplier becomes a major challenge.

Why Engineered Plastic Sourcing in Vietnam Is Difficult

1. Most factories only mold common plastics (PP, PE, ABS…)

Vietnam has many plastic injection suppliers. Still, most of them focus on commodity plastics such as PP, PE, ABS, or HIPS. They produce consumer goods and large-volume items. As a result, they rarely invest in advanced tooling or engineering skills. Therefore, they cannot support engineered plastics or high-performance grades.

2. Only a few factories can handle engineering plastics (PS, POM, PMMA, PC, PA…)

A smaller group can mold engineering plastics. Even so, their experience is often limited. Many can inject POM or PMMA, yet only for simple parts. They may not manage tight tolerances or complex molding requirements. Because of this, only a small number of factories truly meet engineering expectations.

2.1. Very few factories can produce small, precise, or micro-injection parts

Most factories in Vietnam produce large plastic items or household goods. These categories do not need high precision. That is why only a very small number can make small components, precision parts, or micro-injection pieces.

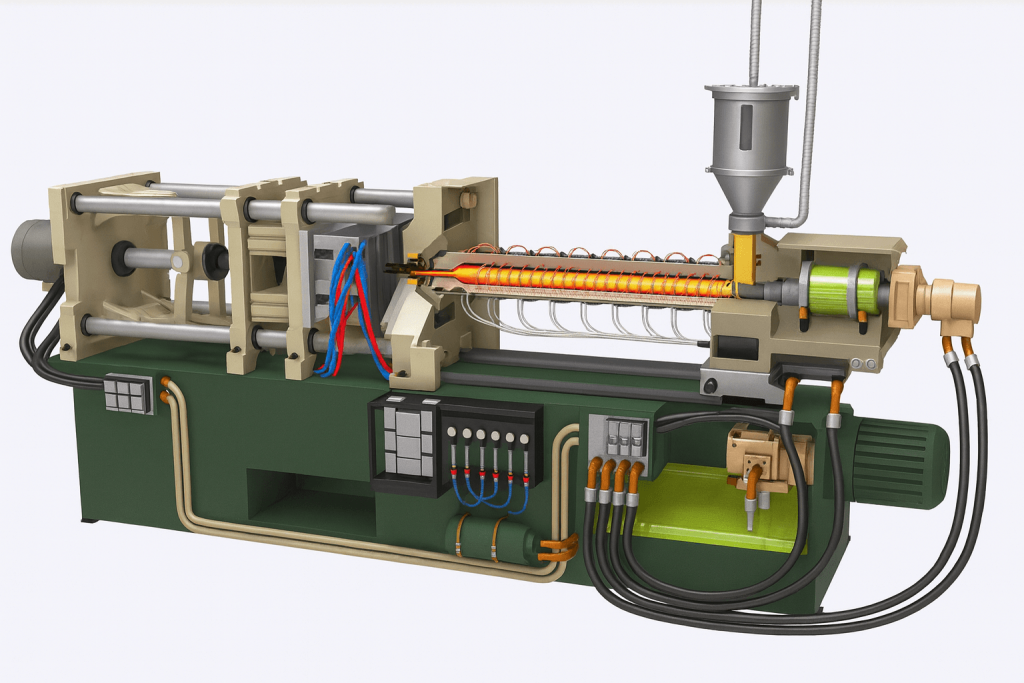

Micro-injection requires advanced machines, stable temperature control, and skilled operators. Since most suppliers do not have these capabilities, we must filter hundreds of factories to find the right ones. This step allows us to deliver faster and more accurate solutions for buyers.

3. Almost no factories accept specialty materials like UHMWPE

The biggest challenge comes from high-performance plastics such as UHMWPE, PPS, or PEEK. These materials need special tooling, advanced process control, and the correct screw setup. In reality, almost no factory in Vietnam has experience molding UHMWPE.

Some suppliers decline the project, while others accept without understanding the technical risks. Because of this, buyers lose weeks in communication and sampling before realizing the supplier is not suitable. This leads to delays, repeated failures, and extra sourcing costs—especially when the sourcing agent does not have technical knowledge.

How Vietnamsourcing.net Helps Buyers Find the Right Factory Faster

At Vietnamsourcing.net, we support U.S. buyers by connecting them with capable plastic injection factories in Vietnam. We do this by mixing engineering experience with data-driven research. This approach makes Plastic Injection Sourcing in Vietnam faster and more accurate.

1. Engineering Team With 10+ Years of Experience

Our engineers have more than a decade of hands-on experience. They understand injection molding and engineered materials deeply. This allows us to:

- Read drawings correctly

- Understand tolerance requirements

- Predict molding risks early

- Check real supplier capability

- Reduce the vendor list quickly

Because of this, buyers avoid wasting time with factories that cannot support their projects.

2. Global Trade Data Used to Filter Factories Instantly

We do not rely on Google searches or guesswork. Instead, we use global trade data to confirm real factory capability. Through trade records, we can identify:

- Factories that import UHMWPE or engineering-grade resin

- Suppliers that export engineered plastic parts

- Their product range

- Their export history

- Their ability to handle similar materials

Since our method uses real data, we match buyers with suitable suppliers within hours, not weeks.

3. Buyers Save Time, Reduce Risk, and Avoid Costly Mistakes

Our combined engineering and data approach helps buyers avoid:

- Talking to dozens of factories with no capability

- Repeating failed samples

- Delays caused by poor supplier fit

- Paying sourcing agents without technical knowledge

- Wasting time on suppliers that only “say yes”

Instead, buyers receive a short list of capable factories that match their material and performance needs.

Conclusion: Vietnam Is Strong, but Supplier Selection Matters

Vietnam is a strong base for plastic injection. Yet, many factories focus only on standard materials. Only a small number can support engineered plastics, and almost none can work with specialty materials like UHMWPE. Therefore, the right supplier choice is critical.

At Vietnamsourcing.net, we help buyers make that choice by combining:

- Engineering expertise

- Local supplier knowledge

- Verified global trade data

This approach allows U.S. buyers to source engineered plastic injection parts—including UHMWPE—faster and with higher success rates.

To know more or further support, please find us HERE