What Is a Roller Chain and What Is It Used For?

A roller chain is a mechanical chain used to transfer power between rotating shafts. It is widely used in machines that need stable and continuous motion.

A roller chain includes rollers, pins, bushings, and link plates. Because of this structure, it can handle heavy loads and long working hours.

As a result, roller chains are reliable and durable. Therefore, they are critical parts in many industrial systems.

Common Applications of Roller Chain

Because of their strength and stability, roller chains are commonly used in:

- Industrial machinery and automation

- Conveyor and material handling systems

- Agricultural machines

- Packaging and processing lines

- Power transmission equipment

- Heavy-duty mechanical applications

Roller Chain Vietnam: Current Local Supply Chain

In Southeast Asia, the supply chain for US-qualified roller chains is very limited. In fact, only two factories in the region supply roller chains directly to US retailers.

These factories are located in:

- Vietnam

- Thailand

As a result, Roller Chain Vietnam has become a rare sourcing option. At the same time, it helps buyers reduce dependence on China.

Unlike many mechanical products, roller chain manufacturing has high entry barriers. Therefore, only a few factories can meet US quality and compliance standards.

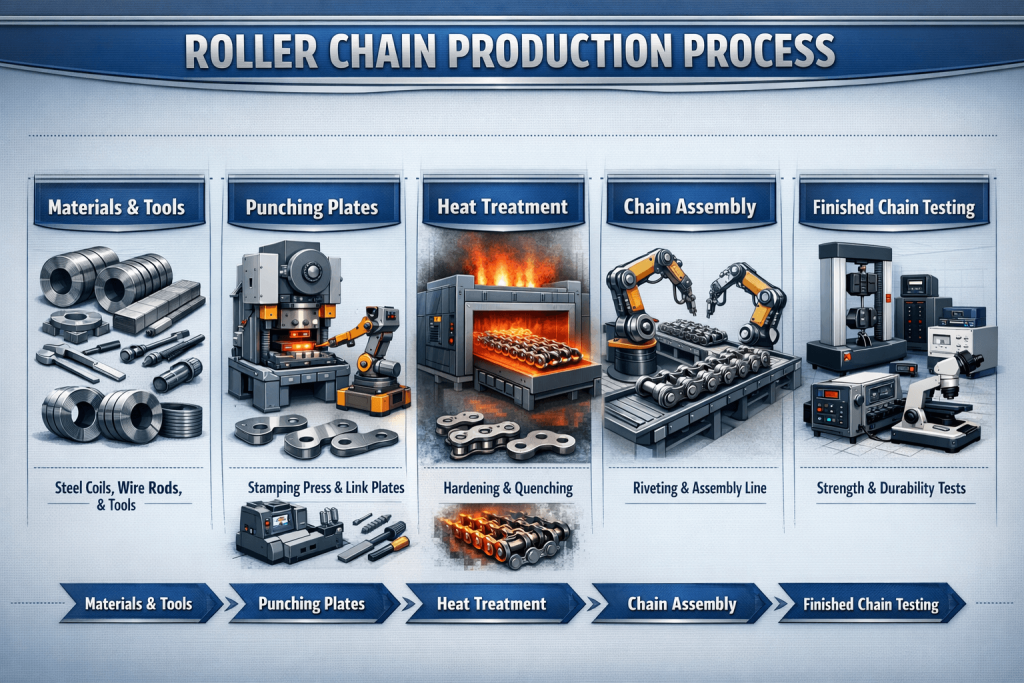

Roller Chain Vietnam Production Process

A US-qualified roller chain factory usually runs a fully integrated production process.

1. Materials, Tools, and Machines

- Specific steel grades for roller chains

- Dedicated punching and heat treatment machines

- In-house testing equipment

2. Punching Plates

- Precision stamping of link plates

- Tight control of size and tolerance

3. Heat Treatment

- Heat treatment for pins, bushings, and rollers

- Direct impact on strength and service life

4. Chain Assembly

- Accurate assembly of all components

- Control of alignment and tension

5. Finished Chain Testing

- Tensile strength testing

- Wear and fatigue testing

- Dimensional inspection

As a result, only factories with full process control can supply the US market.

Why Roller Chain Vietnam Is Rare in Southeast Asia

There are several reasons why Roller Chain Vietnam remains a niche category.

First, roller chains require specific steel materials, not common mechanical steel. Second, production needs product-specific machines with high investment costs.

In addition, factories must install advanced testing equipment. Moreover, US market entry requires strict compliance and product liability control.

Finally, long-term experience matters. Most qualified factories have supplied US buyers for many years. Because of these factors, very few factories can meet all requirements at once.

How Vietnamsourcing.net Helps Buyers Find the Right Factory Faster

Because the Roller Chain Vietnam supply base is small, sourcing independently can be risky.

1. Direct Access to Qualified Factories

Vietnamsourcing.net works directly with:

- The qualified roller chain factory in Vietnam

- The qualified roller chain factory in Thailand

As a result, buyers can:

- Reach proven suppliers immediately

- Avoid trial-and-error sourcing

- Compare options faster

2. Factory Verification Using Global Trade Data

To confirm real production and US exports, we use:

- Import and export shipment data

- Historical trade records

- US consignee verification

Therefore, buyers avoid unproven or non-qualified suppliers.

Final Thoughts on Roller Chain Vietnam

Overall, Roller Chain Vietnam is not a mass-market product. Instead, it is a high-bar mechanical category.

It requires the right materials, special machines, strict testing, and US market experience. Because of this, choosing the correct factory from the start is critical.

As a result, Vietnamsourcing.net helps buyers shorten sourcing time from months to weeks. We do this through verified factories, global trade data, and deep local supply chain insight.

If you want to explore more about sourcing from Vietnam, you may find this guide helpful.