Why Choose a Fully Integrated Partner in Vietnam

Vietnam has become a key sourcing destination for aluminum extrusion manufacturers.

As a result, many U.S. and North American buyers now look to Vietnam as an alternative to China.

However, not all aluminum extrusion manufacturers operate at the same level.

While many factories offer extrusion or surface finishing, very few run a fully integrated, in-house process.

This process includes billet melting, extrusion, surface treatment, and final fabrication.

Therefore, for buyers facing tariff pressure and compliance risk, this difference is critical.

Aluminum Extrusion Manufacturers in Vietnam: The Reality

Vietnam has many aluminum extrusion manufacturers.

However, most factories operate with partial processes, not full integration.

Many buyers assume extrusion manufacturers control the entire process.

In reality, this assumption is often incorrect.

As a result, buyers may unknowingly work with multiple subcontractors.

This setup increases risk and reduces control.

In-House Billet Melting: A Rare Capability in Vietnam

Most aluminum extrusion manufacturers in Vietnam import aluminum billets instead of melting them in-house.

China remains the most common source because of lower cost.

However, this practice creates serious risks as the U.S. increases scrutiny on aluminum imports.

Key risks include:

- Exposure to transshipment investigations

- Difficulty proving true country-of-origin

- Higher risk under U.S. tariff enforcement

Factories with in-house billet melting can:

- Control alloy composition, such as 6061 and 6063

- Provide full material traceability

- Reduce tariff and compliance risk for U.S. buyers

In addition, in-house melting improves long-term cost stability.

Factories become less exposed to billet price swings and overseas supply disruptions.

Extrusion: Not Always Done In-House

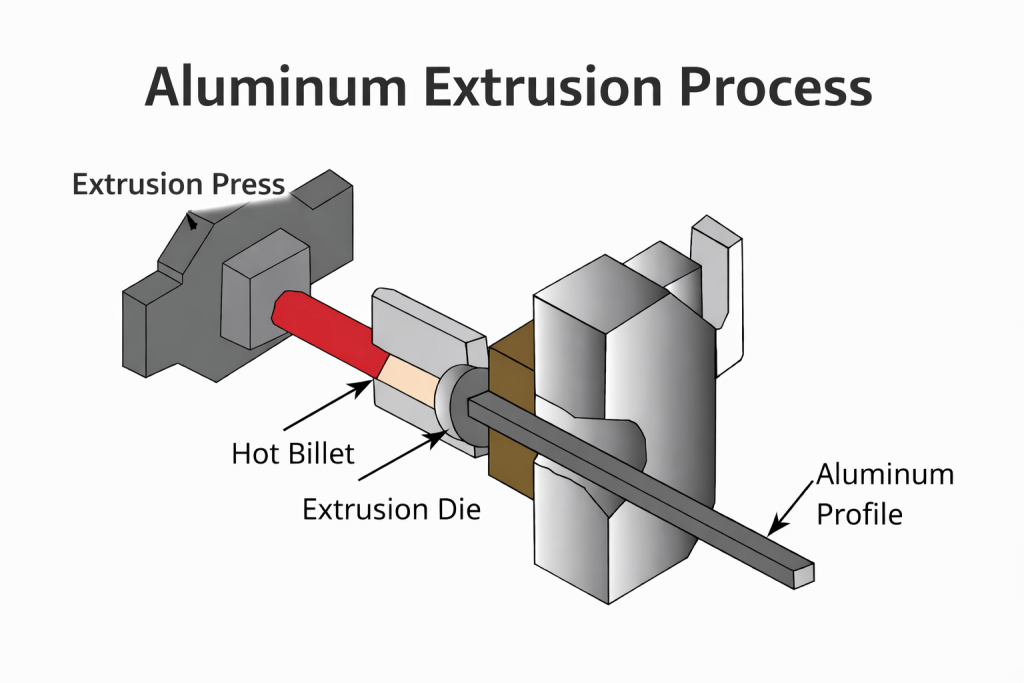

Extrusion, often called operating an extruder, is the core step in aluminum profile production.

However, not all aluminum extrusion manufacturers perform extrusion themselves.

Some factories outsource extrusion to third-party plants.

They only handle simple post-extrusion work and packaging.

As a result, this setup limits:

- Process control

- Dimensional accuracy

- Production consistency

For buyers with tight tolerances, outsourced extrusion increases batch variation.

Moreover, it makes root-cause analysis harder when quality issues appear.

Anodizing and Powder Coating: Closely Linked to True Extruders

Only factories that extrude in-house usually invest in anodizing or powder coating lines.

These surface treatments connect directly to the extrusion process.

Depending on customer needs:

- Anodizing improves corrosion resistance and appearance

- Powder coating adds durability and color flexibility

When finishing stays in-house, profiles move directly from extrusion to treatment.

Therefore, factories reduce oxidation, handling damage, and rework between subcontractors.

Fabrication: The Biggest Gap for Buyers

Fabrication includes CNC machining, stamping, bending, cutting to length, assembly, and packaging.

However, many aluminum extrusion manufacturers do not offer fabrication.

They avoid fabrication because:

- It needs extra equipment and skilled labor

- Customer volumes may not justify new investment

- Setup costs remain high for small or custom orders

As a result, buyers struggle to find factories with full process capability.

Because of this, strict buyers now require a one-stop supplier.

They prefer finished components, not raw aluminum profiles.

This approach reduces coordination effort, logistics complexity, and quality risk.

U.S. Tariffs and the Push for Full In-House Processing

Under U.S. tariff pressure, North American buyers now demand:

- In-house processing, or

- Fully local sourcing within one country

The goal is clear:

- Minimize tariff exposure

- Prove clear country-of-origin

- Avoid transshipment blacklists

However, this remains difficult when buyers lack local insight.

It also becomes harder when suppliers operate with fragmented processes.

With Section 232 aluminum tariffs and stricter enforcement, factories without in-house melting or fabrication may fail compliance checks.

Even competitive pricing cannot offset this risk.

Why Fully Integrated Aluminum Extrusion Manufacturers Stand Out

A vertically integrated aluminum extrusion manufacturer offers:

- In-house billet melting

- In-house extrusion

- In-house surface finishing

- In-house fabrication and packaging

This model delivers:

- Stronger quality control

- Shorter lead times

- Better cost transparency

- Easier auditing and compliance

For U.S. buyers, full integration reduces supply chain risk.

Over time, it also shifts sourcing from transactional buying to long-term partnership.

Final Thought

Vietnam has many aluminum extrusion manufacturers.

However, fully integrated factories remain rare.

By understanding this difference, buyers can avoid compliance risk and hidden costs.

More importantly, they can build stable supply chains in a tariff-sensitive environment.

To know more or further support, please find us HERE