Introduction

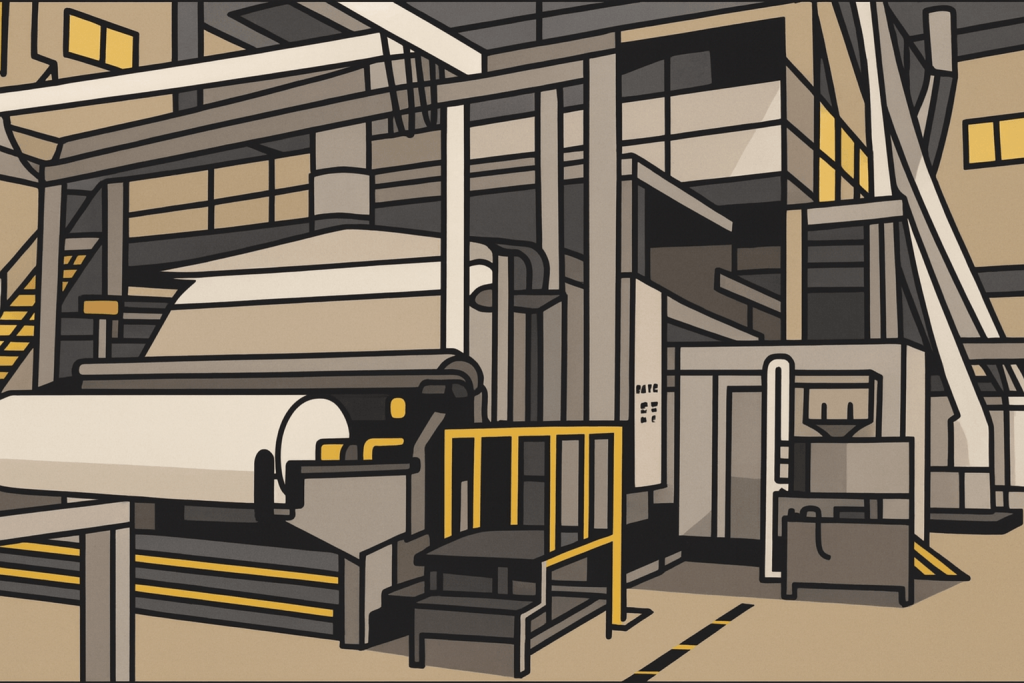

Vietnam has become one of the most active non-woven manufacturing hubs in Southeast Asia. The country produces PP spunbond, PET non-woven, spunlace, and needle-punched fabrics. However, when it comes to Electret Non-Woven Fabric Vietnam, the supply chain looks very different. Many factories can produce basic non-woven materials, yet they cannot make electret-grade fabric because they lack charging technology and advanced filtration systems.

Because of this gap, buyers often feel confused. Vietnam has many non-woven factories, but they still cannot find the exact electret material they need. This post explains the local supply chain clearly and shows how electret development is slowly emerging in Vietnam.

What Makes Electret Non-Woven Different?

Electret non-woven plays a key role in filtration products such as N95 masks, HVAC filters, and industrial dust-control materials. Standard PP non-woven can hold a short-term static charge, but this charge fades quickly. However, electret material keeps its charge for much longer due to additional processing steps such as:

- Corona charging

- Hydrocharging

- Plasma or tribocharging

- High-precision melt-blown filtration testing

These steps help the fabric capture tiny particles while still allowing airflow. Because most Vietnamese factories produce basic non-woven materials, the country does not yet have strong capacity for true electret-grade production.

Electret Non-Woven Fabric Vietnam: Current Local Supply Chain

The non-woven supply chain in Vietnam has grown quickly in recent years. Even so, one main limitation remains clear: there is still no domestic mass-production of electret melt-blown fabric. Today, Vietnam’s main non-woven capabilities include:

- PP spunbond for bags and hygiene

- PET non-woven for automotive and furniture

- Needle-punched fabric for footwear and construction

- Spunlace for wet wipes

- Melt-blown for basic filtration (without electret treatment)

Electret charging units were not widely installed in Vietnam, even during the COVID period. As a result, factories can make melt-blown material, but it is not electret-grade. Because of this, buyers searching for Electret Non-Woven Fabric Vietnam often need to import electret material from China or explore R&D with selected Vietnamese suppliers.

Why Electret Non-Woven Is Rare in Vietnam

Several reasons explain why electret production remains very limited:

1. High investment cost

Electrostatic charging systems and testing equipment require large investment. Most factories were built to supply basic non-woven needs, not filtration-grade products.

2. Technical complexity

Electret melt-blown requires stable PP resin, consistent MFI levels, and tight process control. Only a few factories in China have mastered these requirements.

3. Limited domestic demand

Vietnam does not have a large market for high-grade filtration materials. Therefore, factories do not want to invest heavily in such specialized equipment.

4. Engineering limitations

Electret development needs strong polymer engineering and clean-room environments. Few factories in Vietnam have this level of expertise.

Because of these factors, most Vietnamese factories focus on high-demand, lower-complexity materials instead of advanced filtration products.

Is Development Possible in Vietnam?

Yes, development is possible, but success remains rare. Some large non-woven manufacturers in Vietnam are willing to test electret production if buyers provide:

- Clear filtration standards

- Resin specifications

- Long-term volume commitments

Vietnam also has technical universities with polymer labs that can support early R&D. However, development requires time, repeated testing, and strong cooperation between buyers and factories.

How Vietnamsourcing.net Helps Buyers Find the Right Factory Faster

1. We Developed a Vietnamese Factory That Already Produces Electret Non-Woven Fabric

Vietnamsourcing.net has successfully worked with a leading non-woven factory in Vietnam to develop electret-grade non-woven material. This factory has already exported electret fabric to Australia and the EU, which confirms its capability and stability.

Because of this success, buyers can start production immediately. They do not need to wait for R&D, testing, or engineering validation. This advantage helps them move faster and reduce sourcing risks.

2. We Use Global Trade Data to Identify the Right Factories Instantly

Our sourcing method uses global trade data to filter factories based on real export performance. We can see which factories ship to the US, EU, and Australia, and which products they supply. This data-driven approach removes guesswork and helps buyers avoid unqualified suppliers. As a result, sourcing becomes faster, clearer, and more accurate.

Conclusion

The supply chain for Electret Non-Woven Fabric Vietnam is still limited. Most Vietnamese factories cannot produce electret-grade material today. Even so, several development projects have started, and some have already shown real results—especially through Vietnamsourcing.net.

With proven supplier development, strong data tools, and deep local insights, buyers can now access electret-grade non-woven from Vietnam or combine Vietnamese production with imported raw materials. As global sourcing continues to diversify, Vietnam is becoming an important alternative for advanced non-woven materials.

To know more or further support, please find us HERE