When U.S. buyers source high precision parts, quality control is not a formality.

Instead, it is a core requirement.

Tolerance is tight. Variation is not acceptable. Consistency is mandatory.

Therefore, our quality control approach follows U.S. engineering logic, not basic factory inspection habits.

Below is how we control quality for high precision parts projects from the U.S. side.

PPAP – Production Part Approval Process for High Precision Parts

For high precision parts, PPAP confirms that the process runs consistently.

It does not focus on one good sample.

Moreover, we apply PPAP at five levels. The level depends on part risk and tolerance.

PPAP Levels (Summary):

- Level 1 – Part Submission Warrant (PSW) only, used for very low-risk precision parts

- Level 2 – PSW plus limited supporting data, such as dimensional results

- Level 3 – Full PPAP package, most common for U.S. high precision parts

- Level 4 – Customer-defined requirements, often used for pilot or special cases

- Level 5 – Full PPAP with on-site review, used for critical components

In real projects, Level 3 is the default for U.S. buyers sourcing high precision parts.

PFMEA – Process Failure Mode and Effects Analysis

PFMEA is used before mass production.

As a result, problems are prevented early.

For high precision parts, PFMEA helps us:

- Identify where tolerance may drift

- Analyze tooling wear risks

- Evaluate operator and machine variation

- Prevent hidden defects early

Therefore, corrective actions are defined before the first production run.

Cp / Cpk – Evaluating Process Capability and Stability

For U.S. buyers, meeting tolerance once is not enough.

Instead, the process must stay stable over time.

We use Cp and Cpk to evaluate:

- Whether the process meets tolerance limits

- Whether production stays centered

- Whether variation is acceptable for scale-up

Typical expectations for high precision parts include:

- Cpk ≥ 1.33 for standard precision

- Cpk ≥ 1.67 or higher for critical parts

If Cpk does not meet the target, production does not move forward.

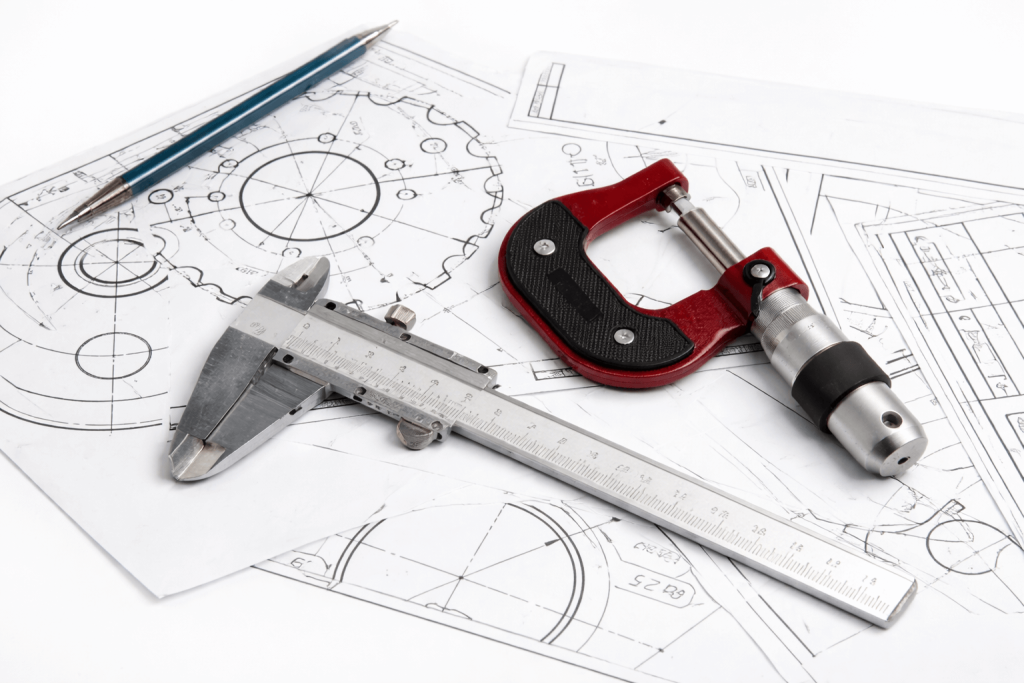

Control Plan – How We Control High Precision Parts on the Shop Floor

A control plan shows how quality is controlled every day.

It does not stop at final inspection.

For high precision parts, the control plan defines:

- Which dimensions are checked

- Inspection frequency

- Measurement methods and equipment

- Reaction plans when results go out of control

As a result, operators, QC staff, and engineers follow the same standard on every shift.

Final Thoughts for U.S. High Precision Parts Buyers

For U.S. buyers, quality control is not about paperwork.

Instead, it is about confidence.

Confidence starts with a clear understanding of the process.

Next, we identify risks early.

As a result, production remains stable over time.

Therefore, PPAP, PFMEA, Cp/Cpk, and control plans work together to answer one key question:

Can this factory repeatedly produce the same high precision parts within tolerance, at scale?

If the answer is yes, the supplier is qualified.

However, if the answer is no, price and speed no longer matter.

That is how U.S. buyers evaluate high precision parts suppliers.

To know more or further support, please find us HERE