What is the difference between 3 and 5-axis Machining?

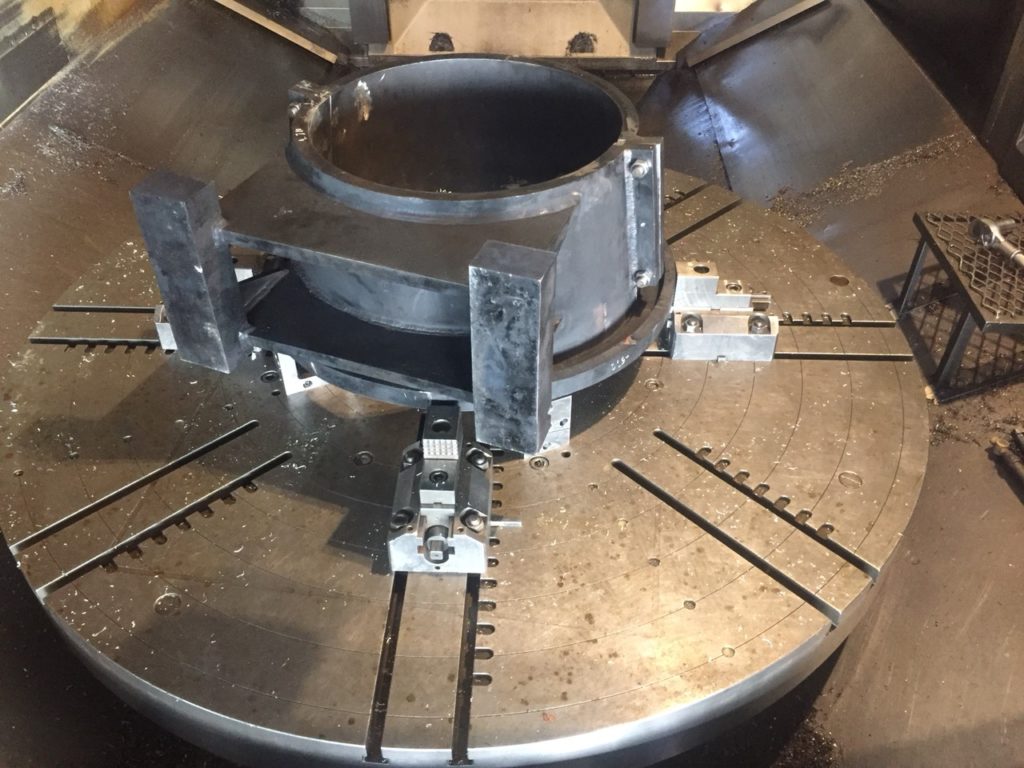

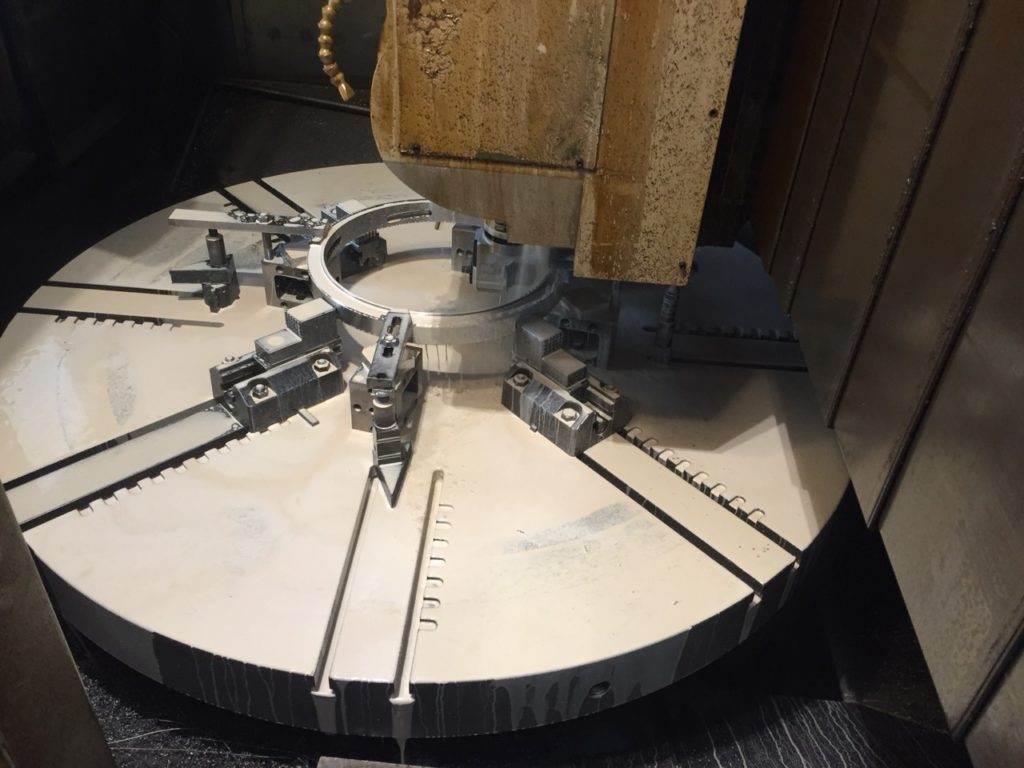

Machining parts sourcing with 5 axis process – a simple 3 axis milling machine allows a part to be worked in 3 axes (X, Y and Z). These CNC machines work perfectly well and are capable of machining many parts. Problems arise when the part requires deep, narrow pockets. The work becomes very labour intensive and leaves a sub-standard finish.

Over the years technology advanced with CAM technologies 3+1 axis, 3+2 axis and finally 5-axis machines being developed to allow the cutting tool to reach more of a component’s surface. Now, with 5 axis machining the possibilities are endless!

Why choose 5-axis Machining?

A 3-axis milling machine will produce perfectly fine parts – up to a point. The additional two axes on a 5-axis machine enable greater machining control and precision. This allows engineers to produce components with complex features that once seemed impossible.

5 axis capability means fewer operations and associated tasks, saving us time and you money, because:

- programmers write fewer programs

- we need fewer fixtures and tools

- machine operators have less work to do on your project

Axis Precision Engineering

We’re ready to work with your company to engineer the parts you need to the specification you require! It’s easy to get a quote, Contact Mr. Mike Johnson at mjohnson@vietnamsourcing.net to discuss your plans for Machining Parts Sourcing a low cost manufacturing solution in Vietnam.