Vietnam Manufacturing Sourcing – You’ve probably seen the terms “ODM” and “OEM” before. And chances are, wherever you’re sitting right now, you’re within arm’s reach of several ODM and OEM products. Understanding these terms and the difference between them is an important step in setting yourself up to be an importing entrepreneur.

Original Design Manufacturing

ODM, or original design manufacturing, is also also referred to as “private labeling.” This is where an importer selects an already-existing product design from a factory catalog, makes a few small changes and sells it under their own brand name. Changes can include things like packaging or product bundles, colors and branding, and some limited adjustments to components or functionality

Two ODM laser pointer cat toys. While both products are manufactured according to the same general design, each is custom branded, colored and packaged according to each buyer’s specifications. ODM doesn’t just refer to electronics though. Ever notice how most American Chinese take-out menus look the same? This is another example of ODM manufacturing. A manufacturer (in this case, a printer) keeps a template on file that buyers can customize to fit their specific needs.

The advantage of ODM is that it spares importers the need to invest millions of dollars into research and development in order to create a new product from scratch. Why reinvent the wheel when you can just improve one that already exists? And by eliminating or vastly reducing the expense of product development, importers can focus more on marketing strategies.

The disadvantage of ODM is that it can be more difficult to differentiate your product from competitors’ products that are manufactured according to the same design. Although ODM requires less start-up capital, price competition tends to be steeper, resulting in slimmer profit margins. For example, a customer looking to purchase an ODM laser pointer is more likely to choose based on price than based on differences in color or brand. To really differentiate your ODM product from the others on the market, while still remaining competitive price wise, can require a significant amount of creativity.

Original Equipment Manufacturing

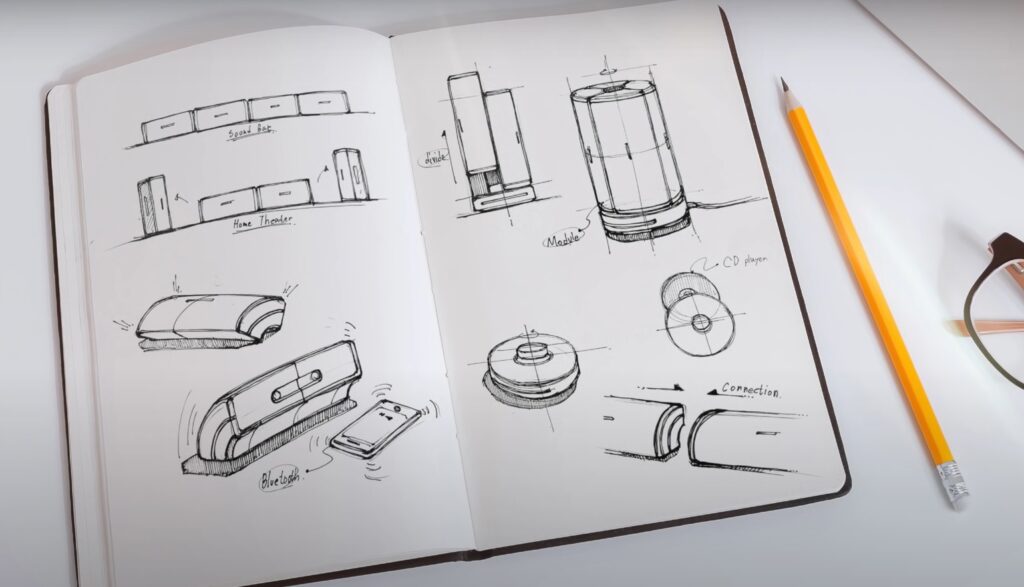

OEM stands for Original Equipment Manufacturing, and refers to products that are fully designed by one company and then licensed out to a manufacturer to produce. The Apple iPhone, for example, invented and designed by Apple, and then licensed out to Foxconn to produce. As a result, the iPhone enjoys a higher level of product differentiation because its design is only available to Apple and its licensed manufacturer.

Many other brand name electronics and appliances are OEM. Custom designed clothing, as opposed to a generic garment with a custom logo, is another example of OEM.

The main advantage of OEM is that the designer retains total creative control over the design. Whereas ODM products are restricted to a predetermined design, OEM products made according to any specifications. The only limitation is the designer’s imagination (as well as budget).

The disadvantage of OEM manufacturing is that it is much more resource intensive. OEM designers often invest millions of dollars into research and development over several years in order to create unique products. Because of this, OEM designers have to guard their designs as intellectual property, lest it copy and sold by another company for a lower price.

Check out the summary table below:

ODM

- Little or no costs on R&D

- Lower MOQ for production

- Undifferentiated from other products

- Price competition

- Do not own the IP

OEM

- Unique products

- Customized products

- Own IP

- Expensive cost in R&D

- Higher MOQ for production

- Time-consuming

Vietnam Sourcing – Your trusted sourcing partner in Vietnam

Are you going to source from Vietnam [Vietnam Manufacturing Sourcing], an Asia sourcing hub with great potential. You faced with any problems when sourcing Vietnam? With professional experience and presence at manufacturing locations and economic centres, Vietnam Manufacturing Sourcing thoroughly understands and has the capability to help you break through all the barriers as well as successfully do business in this country. Just leave your comment below or click HERE for further support!