Rubber Parts Sourcing – Transfer Molding

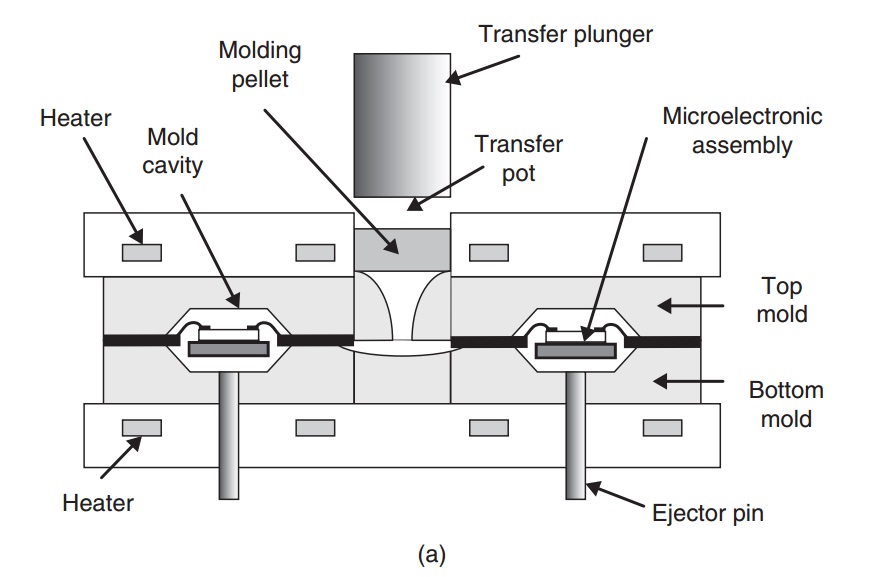

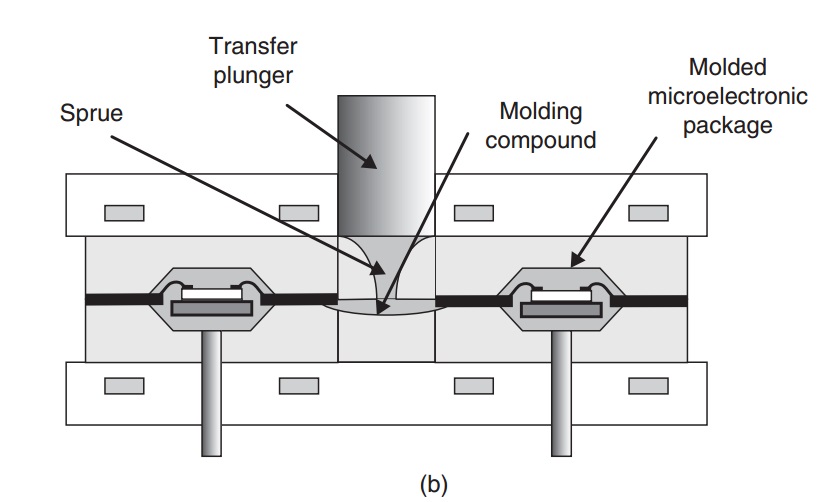

The transfer molding process is the most common method for essentially all plastic packages in integrated circuit technology. Transfer molding is a process of devices in a closed mold using a thermosetting material that is transferred under pressure . Thermosets are polymers that are fluid at low temperatures. And react irreversibly when heated to form a cross-linked network no longer capable of being melted. Figure below depicts the transfer molding process. The preheated molding compound—preform (pellet)—is placed in an auxiliary chamber, called the transfer pot. And is forced by the transfer plunger to flow through runners and gates into the closed cavity or cavities. The transfer molding process offers several advantages over other molding techniques. Due to the extreme high pressure involved during the injection molding process, transfer molding is more suitable for parts with inserts.

The transfer molding process is also more suitable for high production volume and short loading and molding cycle.

Transfer pots can be connected to multiple runners for simultaneous molding of the parts; therefore, fewer and larger molding compound preforms need to be loaded into the transfer pot with relatively shorter loading times compared to multiple transfer pots with fewer runners. The transfer molding technique generally requires low tool and maintenance costs. Deep loading wells are not necessary in transfer molding, and the mold sections can be made thinner because the stresses involved during closing of the mold are lower. The wear of the molds is also lower in transfer molding and the tendency toward breakage of pins is less. As the components are produced in closed molds, which are subjected to less mechanical wear and erosion by the molding material, closer tolerances on all molded dimensions are possible in transfer molding. One of the main limitations of the transfer molding process is the amount of scrap material. The material left in the pot and also in the sprue and runner is irreversibly reacted (cross-linked) and must be discarded.

This is unavoidable and for small articles, it represents a sizable percentage of the weight of the pieces molded. However, in the fully automatic transfer molding presses employed for electronic parts, the savings elsewhere. Including mold costs and finishing costs, usually offsets the loss of material.