At Sourcing in Vietnam, Sampling is the selection of a representative portion of the population to make inferences about the entire population. In pharmaceutical manufacturing, samples are drawn from different stages of the process for both controlling process parameters and assessing drug product quality.

Understanding The Process

To understand why we value sampling as an integral part of the manufacturing process, it is first important to have a better idea of what our sampling process looks like. The goal of sampling is to ensure our clients do not receive a final product that falls short of their exacting specifications. Sampling prevents full production from starting until the sampling approval process has taken place. We ensure that quality is not lost when you outsource your manufacturing. The following are both sampling methods we employ:

- Tooling Approval Samples: A run of the tool in final materials. This also will include inspection reports and required certifications to ensure you have the documentation you need to make the right decisions.

- Pre-production Approval Samples: A pre-production run using final materials. This process will also include “retail-ready” packaging samples if required. Whether or not the “retail-ready” packaging samples are included will be based upon the available design specifications given to us.

Instead of waiting until production is in full-swing, the sampling process allows you to catch discrepancies or failures to meet your specification standards early-on in the process. This can prevent a large number of wasted resources, including both time and money. We understand that you are operating on a tight timeline, which is why sampling is a critical part of the process. Rather than backing up production drastically, sampling allows you to fix problems before they become a full-blown crisis.

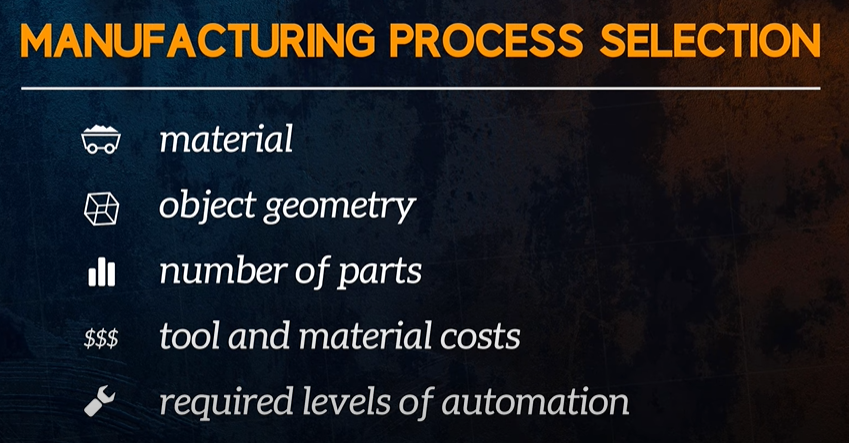

The Five Manufacturing Processes

- Repetitive Manufacturing. A manufacturer would use repetitive manufacturing for repeated production that commits to a production rate. …

- Discrete Manufacturing. …

- Job Shop Manufacturing. …

- Process Manufacturing (Continuous) …

- Process Manufacturing (Batch)

Have Full Control Over The Process

One of the benefits of sampling is that it allows you to retain full control over the manufacturing process, even when you have outsourced your manufacturing. It is a common misconception that by turning to outsourced manufacturing you will lose the ability to retain quality control. While this could be true if you did not have the right relationship constructed, it does not have to be so.

When you work with Sourcing in Vietnam Agent, we will pair you with the perfect manufacturer for your needs and we won’t stop there. We will help you stay in control of the process through a myriad of methods, such as sampling, that ensure you retain control over quality. While outsourcing allows you to turn your focus to other important matters, it doesn’t leave you in the dark with no control over the process. We believe sampling is an excellent way to help our clients stay connected with the manufacturing process.

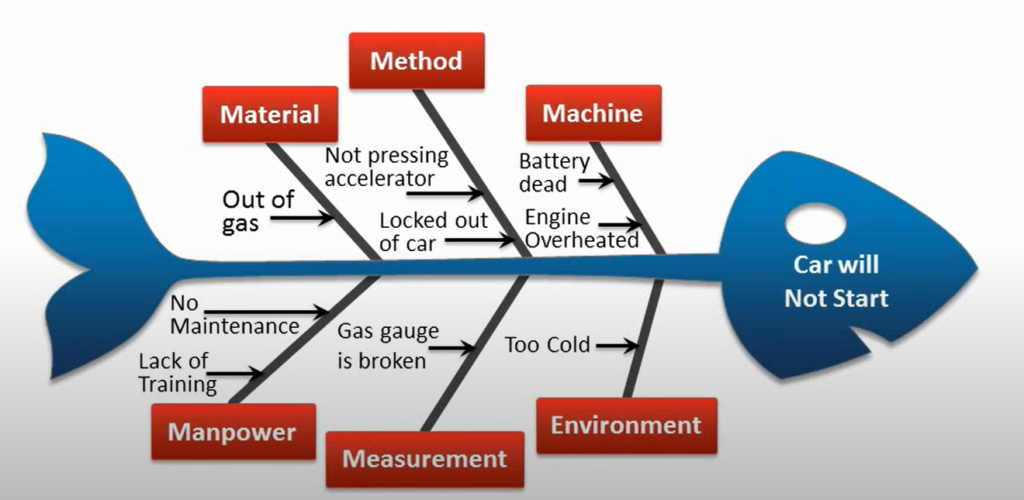

How should I determine sampling requirements? Sampling requirements refer to issues such as how often you should be collecting data and how many measurements are required to gauge an accurate reading for that particular sample.

To determine sampling requirements, first analyze how stable your current level of production currently is. A small amount of variation in terms of production quality will mandate fewer measurements be taken. If you are experiencing unstable production, then you might need to sample as often as every few hours to return to stability.

Work With The Best

At Vietnam Global Sourcing, we are different than any other sourcing provider. We will employ a full sampling approval process. Which allows you to ensure your precise requirements are met and that your product is fit for use before. We ever start the full production process. We maintain such a rigorous process because we firmly believe that outsourcing your manufacturing will only be successful. If you have access to the right supply chain management system.

If you are interested in outsourcing your manufacturing, please reach out to our team today. When you work with Sourcing in Vietnam Agent, you are working with the best. Sampling is just one of many methods we employ to ensure that our clients receive the final product they need. We will help pair you with the perfect manufacturer to help you lower production costs without lowering the quality of your product. Not only can we assist you cutting costs. We can also help you manage your timelines better, leading to fewer hiccups in the process. From the design of your product to the actual logistics of delivering products to your door. We are the turn-key solution you need to access the global network of manufacturing. Reach out today and learn more about how we can help your business succeed.